THE WAR EFFORT IN EAST TENNESSEE

The primary system circulated a coolant through the process equipment to cool the process gas (UF6). The coolant, a special fluorocarbon chemical, would not react with the UF6 if it leaked into the system. (Water was not used for this coolant because it is very reactive with UF6, releasing hydrogen fluoride if they come in contact.) The special coolant was then pumped to the basement vaults where it was cooled in heat exchangers by the secondary cooling system, recirculating cooling water system. The fluorocarbon coolant was then pumped back through the process equipment in this continuous process.

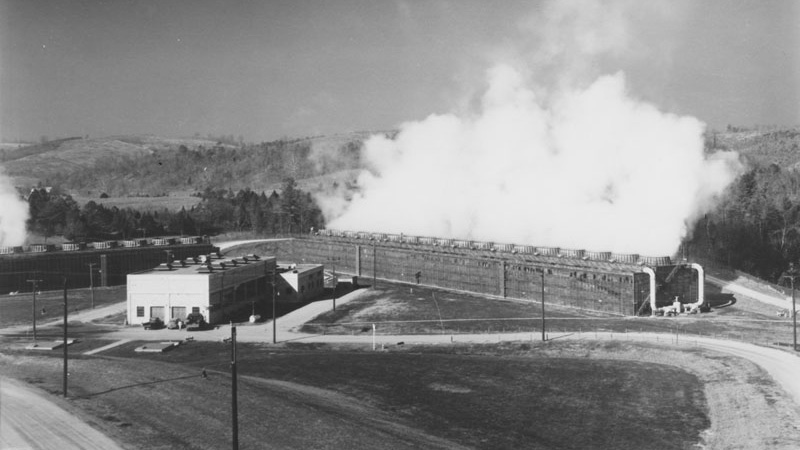

The recirculating cooling water system, built in 1944, handled about 170 million gallons of water a day, enough to supply a city of five million. The system included a pump house, cooling towers, piping to carry the water to and from the process buildings, and cooling tower basins to collect the water.

The RCW system was supplied with water via a pump house that pumped from Poplar Creek to treatment basins where water softeners, corrosion inhibitors, and algaecides were added. The water was then pumped into the process building (K-25) by large pumps located in the Pump House (K-802). The RCW then cooled the fluorocarbon coolant and returned to the cooling towers where the heat was removed by evaporation as it cascaded over the cooling tower fill. As the water fell through the cooling tower, it collected in the basin under the tower where the pump house once again pumped it back through the system starting the cooling cycle again.

The K-802 Pump House was demolished in 2018.

<< BACK